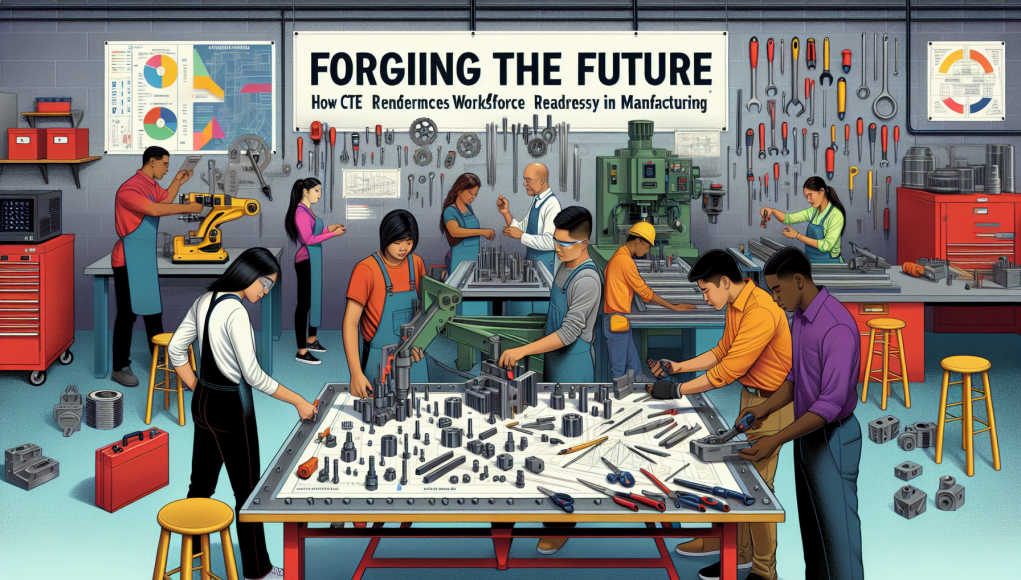

Forging the Future: How CTE Reinvents Workforce Readiness in Manufacturing

As National Career and Technical Education (CTE) Month unfolds, the time is ripe for industry professionals, especially those in the manufacturing sector, to recognize and celebrate the profound impact of CTE programs in bridging the gap between education and employment. In an era defined by rapid technological advancement and ever-evolving manufacturing processes, equipping the workforce with relevant skills is paramount. CTE programs have emerged as a groundbreaking solution, aligning educational curricula with real-world industry needs, thereby fostering a more effective transition from classroom learning to the manufacturing floor.

Manufacturing, with its dynamic and technical nature, requires a workforce that is not just knowledgeable, but also adaptable to new technologies and systems. Traditional educational pathways often fall short in preparing students for the specific demands of modern manufacturing roles. Enter Career and Technical Education, which integrates academic learning with practical skills, ensuring students are job-ready upon completion of their studies. This is particularly crucial in manufacturing, where the ability to operate complex machinery, adhere to safety protocols, and embrace digital technologies is part of everyday responsibilities.

Real-World Preparation

CTE programs provide students with hands-on experience and on-the-job training, often in collaboration with local businesses and industry leaders. This approach not only enhances learning but also ensures that students are proficient with the tools and technology they will encounter in their professional lives. For manufacturing professionals, CTE programs develop competencies in areas such as computer-aided design (CAD), robotics, automation, and green manufacturing technologies.

By aligning training with industry standards, these programs produce graduates who can seamlessly integrate into the workforce, decreasing the need for extensive retraining and reducing turnover rates. In essence, CTE serves as a bridge that fills the void between theoretical knowledge and applied skills, crafting a workforce ready to meet the challenges of modern manufacturing head-on.

Closing the Skills Gap

The manufacturing industry is facing a well-documented skills gap, exacerbated by retirements and a lack of adequately trained new entrants. CTE programs are instrumental in closing this gap by providing a pipeline of skilled workers who have been trained in the very competencies the industry demands. Moreover, CTE fosters critical thinking, problem-solving, and teamwork skills, which are essential in manufacturing environments.

Furthermore, with an increased focus on advanced manufacturing and Industry 4.0 technologies, CTE programs are adapting to include emerging skills such as data analytics, cybersecurity, and IoT device management. This adaptation ensures that the workforce is not only ready for todays demands but is also prepared for the innovations of tomorrow.

The Path Forward

The future of the manufacturing industry depends significantly on its ability to draw from a skilled and versatile pool of professionals. CTE is not just a stopgap measure; it is an enduring strategy that aligns educational outcomes with industry needs, setting the stage for sustainable growth and innovation. As we celebrate National CTE Month, it is crucial to encourage partnerships between educational institutions and manufacturing entities, fostering environments where learning and industry-specific training occur symbiotically.

Ultimately, the success of the manufacturing industry hinges on a well-prepared workforce, ready to tackle the complexities of modern manufacturing. Acknowledging and supporting CTE programs will ensure that the industry continues to thrive, driven by a generation of workers who are not only skilled but are also agile and prepared for the challenges and opportunities that lie ahead.